Description

Foilboard Standard Tek Screws for 10mm and 15mm Sheets

The Foilboard Standard Steel Screws consist of a 50mm x 35mm plastic washer with a pre-punched screw. These screws are specifically designed for fastening Foilboard® to steel frames. Each tek screw comes with a 30mm screw that is suitable for both Standard 10 and Super 15 Foilboard® Sheets. Foilboard recommends using a fastener every 600mm to ensure proper and secure installation.

Foilboard Fasteners for Steel Frames

Foilboard Australia Pty Ltd specializes in manufacturing a comprehensive range of fixing accessories specifically designed to meet the needs of various construction applications. These include the reliable Foilboard Tek Screws, which play a crucial role in ensuring the correct installation of the material and maintaining its thermal performance throughout the lifespan of the application. Whether the construction project involves timber or steel frame structures, underfloor applications, or even commercial systems, Foilboard® offers a wide range of fixings that are tailored to suit all types of applications.

Key Features 30mm Foilboard Standard Tek Screws

- Secure fastening: The Foilboard Standard Tek Screws provide a strong and secure fastening solution for attaching 10mm or 15mm sheets to steel wall frames, underfloor installations, and purlins.

- Versatile compatibility: These screws are designed to work specifically with Foilboard insulation products, ensuring a perfect fit and reliable performance.

- Ample supply: Each pack contains 250 screws, offering an ample supply to meet the needs of different projects and installations.

- Convenient length: With a length of 30mm, these screws provide optimal fastening capability and are suitable for a variety of applications.

- Durable construction: Crafted from high-quality materials, these screws are built to withstand the rigors of installation and provide long-lasting durability.

- Easy installation: The Foilboard Standard Tek Screws are designed for easy installation, saving time and effort during the insulation process.

Method of Calculating Quantities of Foilboard

- Measure Floor or Wall area.

- Add 5% to area to allow for cutting and waste, deduct window and door openings.

- If using 2.44m sheets divide the area by 2.93 to give the number of sheets required.

- If using 2.70m sheets divide the area by 3.24 to give the number of sheets required.

- Round up to the next full sheet.

- Floor saddles should be on joists at approx 600mm centres and spaced at 200mm from sheet ends.

- For retro-fits Foilboard should span across the underside of joists and between bearers using three Foilboard fasteners per joist. Joins do not need to be made on a joist and you should tape all joins.

- Generally 1 bag of saddles is required for every 45-50m2 and 1 Role of Green Tape will be required for every 100m2. For retro-fits you will generally require 1 bag of Foilboard Fasteners and 1 roll of Green Tape for every 15-20 sheets, for Aluminium tape you will require one roll for every 10-12 sheets approx. Flexifastners should be used for all sheets 25mm or thicker and you will require 1 bag of 200 fastners for every 15-20 sheets. Or for sheets over 25mm in thickness you can order the plastic plates and supply your own fixing nails or screws. Spacers for brick work you will require 8-10 spacers per m2

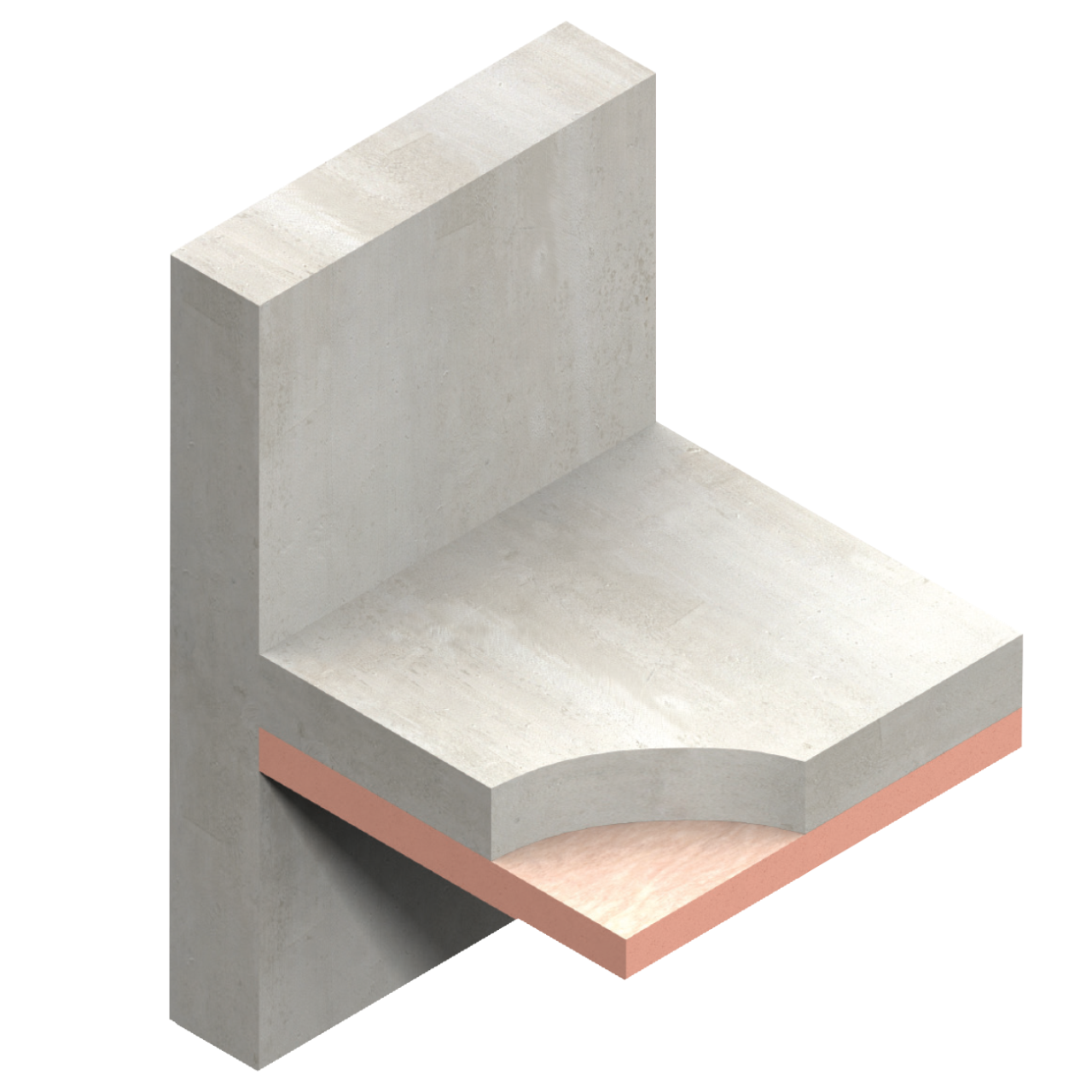

Residential Wall

For example, an area of 130m2 (residential wall – timber/steel frame excluding windows) will require;

- 45 sheets of Foilboard® Insulation Panel (2440mm x 1200mm, 2.93m2 per sheet)

- 3 bags of fasteners (Standard or Ultra)

- 3 Rolls of Green UV PVC Tape

Underfloor Area

For traditional underfloor applications using timber joists at 450mm centres (130m2);

- 45 sheets of Foilboard® Insulation Panel (2440mm x 1200mm, 2.93m2 per sheet)

- 3 bags of Foilboard® Floor Saddles

- 3 Rolls of Green UV PVC Tape