Description

Foilboard Underfloor Saddles

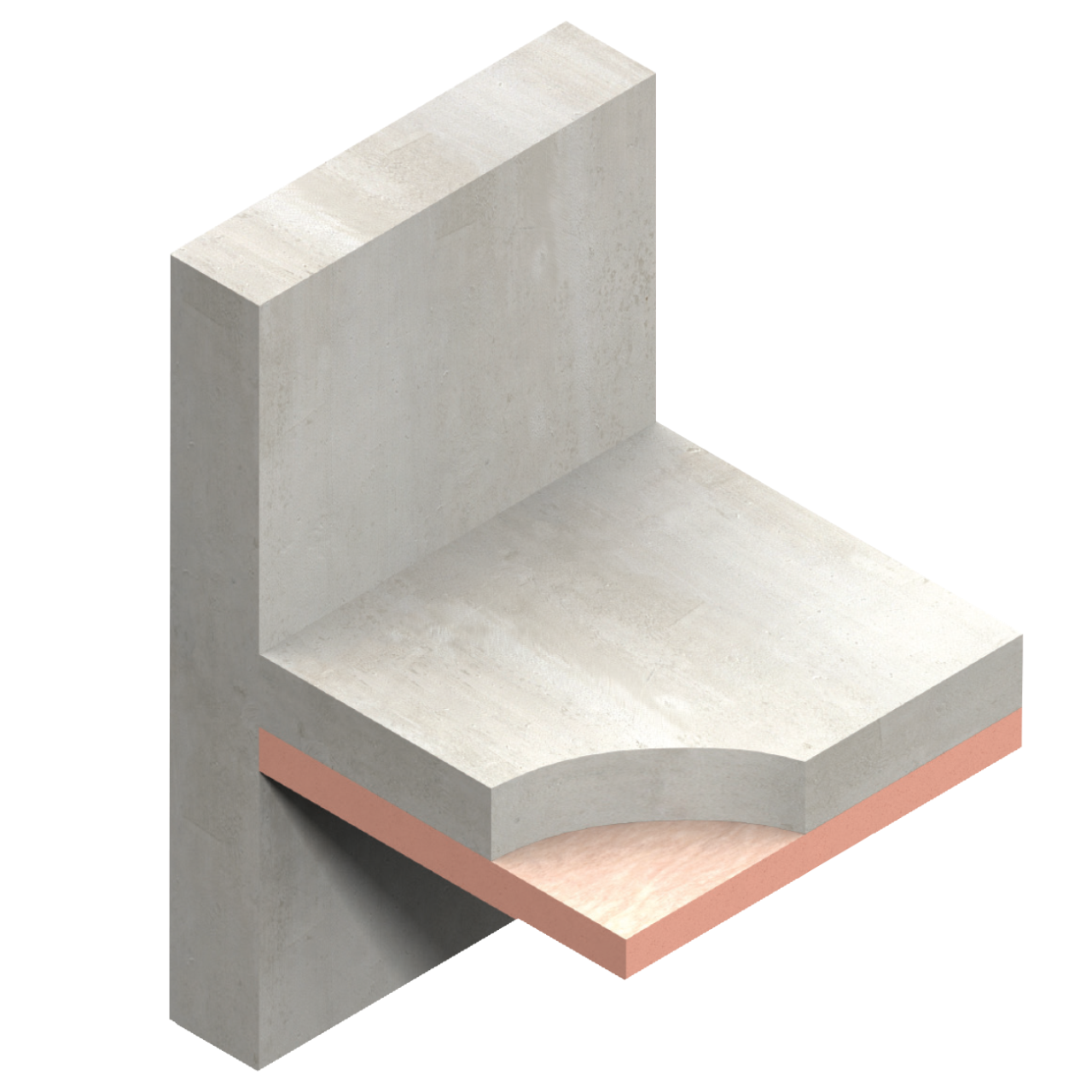

Foilboard Underfloor Saddles play a vital role during the installation of Foilboard prior to laying the flooring. These saddles are positioned beneath the floor joists, resulting in a significant improvement in the thermal performance of the floor while simplifying the process of underfloor joist insulation. The installation process is straightforward: place the saddle over the floor joist and secure it in place using a nail or staple. Next, effortlessly insert the Foilboard® between the floor joists and securely clip it into position.

Foilboard Floor Saddles for Foil Underfloor insulation

Foilboard Australia Pty Ltd manufactures a range of fixing accessories tailored to suit many construction applications. Foilboard timber fasteners are specifically designed to guarantee accurate installation and long-term thermal performance of the material. Regardless of whether the construction involves timber or steel frames, underfloor applications, or even commercial systems, Foilboard® offers a comprehensive range of fixings tailored to suit all types of installations. With Foilboard timber fasteners, you can ensure that your project is equipped with the appropriate fixings for optimal performance and longevity.

Installation suggestions for Underfloor Foilboard

The installation of insulation panels and Floor Saddles is typically recommended after fixing the joists to the bearers and before laying down yellow tongue or strip flooring. It is advisable to complete all plumbing rough-ins and other underfloor services prior to the installation. Foilboard Insulation Panels are lightweight, easy to handle, and safe to work with. They can be easily cut to size using a long snap blade knife, and any off-cuts can be taped and reused.

To install the Foilboard Floor Saddles, space them evenly on top of the floor joists at approximately 600mm intervals. Ensure that the saddles are placed 200mm away from the ends of the sheet. In the case of double joists, the Floor Saddles can be cut in half and fastened with nails. Press the Floor Saddles down so that the specially designed teeth grip the joist securely.

Cut the Foilboard insulation panel to the appropriate size to fit between the joists. Position the panel between the joists, resting it on the lip of the Floor Saddles. Apply gentle pressure to the Foilboard Insulation Panel until it clicks into place, utilizing the patented lock-in flap design. This mechanism helps prevent wind and vermin from disturbing the sheet from underneath. For a seamless finish, it is recommended to tape the joints between the sheets. Additionally, any gaps or holes should be sealed using tape or silicone to prevent air infiltration, which can reduce the overall thermal resistance (R-value).

Method of Calculating Quantities of Foilboard

- Measure Floor or Wall area.

- Add 5% to area to allow for cutting and waste, deduct window and door openings.

- If using 2.44m sheets divide the area by 2.93 to give the number of sheets required.

- If using 2.70m sheets divide the area by 3.24 to give the number of sheets required.

- Round up to the next full sheet.

- Floor saddles should be on joists at approx 600mm centres and spaced at 200mm from sheet ends.

- For retro-fits Foilboard should span across the underside of joists and between bearers using three Foilboard fasteners per joist. Joins do not need to be made on a joist and you should tape all joins.

- Generally 1 bag of saddles is required for every 45-50m2 and 1 Role of Green Tape will be required for every 100m2. For retro-fits you will generally require 1 bag of Foilboard Fasteners and 1 roll of Green Tape for every 15-20 sheets, for Aluminium tape you will require one roll for every 10-12 sheets approx. Flexifastners should be used for all sheets 25mm or thicker and you will require 1 bag of 200 fastners for every 15-20 sheets. Or for sheets over 25mm in thickness you can order the plastic plates and supply your own fixing nails or screws. Spacers for brick work you will require 8-10 spacers per m2

Residential Wall

For example, an area of 130m2 (residential wall – timber/steel frame excluding windows) will require;

- 45 sheets of Foilboard® Insulation Panel (2440mm x 1200mm, 2.93m2 per sheet)

- 3 bags of fasteners (Standard or Ultra)

- 3 Rolls of Green UV PVC Tape

Underfloor Area

For traditional underfloor applications using timber joists at 450mm centres (130m2);

- 45 sheets of Foilboard® Insulation Panel (2440mm x 1200mm, 2.93m2 per sheet)

- 3 bags of Foilboard® Floor Saddles

- 3 Rolls of Green UV PVC Tape